- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

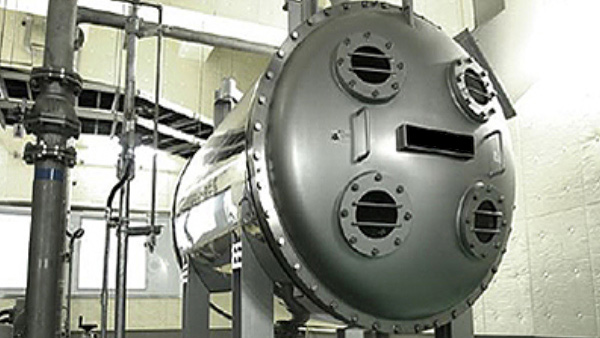

TPI Oil Separator

TPI Oil Separator

CPI/TPI units

We all know the old saying about how oil and water don’t mix. In the waste water treatment industry, however, it’s not so easy to divide these two dissimilar substances. In fact, removing oil from wastewater during processing requires the use of specific equipment.

So, what is the problem with oil? Why does it need to be separated from water? Simply put, it poses an environmental hazard.

Oils found in wastewater include not only the cooking oils and grease that homes, restaurants, and other commercial activities wash down the drain, but also petroleum and other hazardous products. These disrupt ecological systems and are harmful to plants, animals, and us humans.

Of course, there are several equations and formulae that are important to incorporate when it comes to evaluating the appropriate size or style of oil water separator a certain application calls for. But the one to keep in mind is:

Oil + Solids + Time = SLUDGE

Simply put, Krofta’s oil water separator does just what you might expect from the name – it separates oil and suspended solids from water so that it can be skimmed away. I know what you’re thinking. Doesn’t oil separate from water automatically?

It is true that oil and water have a gravitational difference. Oil is lighter than water so it tends to float to the top. However, due to the nature of wastewater, which is suffused with all kinds of contaminants, some oil particulates, especially tiny droplets, can get hung up.

Two Stage CPI/TPI Separator

Oil water separators are designed specifically to target oil based on the gravitational difference between oil and water, allowing for heavier solids (sludge) to settle to the bottom while oil rises to the top, leaving additional wastewater in the middle layer. Sludge can then be scraped away, oil can be skimmed off of the top, and wastewater can move along for further treatment.

As wastewater passes through our separator, oil particulates are tumbled over the surface, allowing them to collect and form larger globules, increasing buoyancy. This, in turn, helps more of the oil to separate and rise above the water.

The stacked plates, increase the surface area the wastewater must pass over, and the fact that they are situated on an incline helps to force the oil up to surfaces where it can coalesce and form larger particles. The oil water separator ensures that the vast majority of oil and sludge is removed before wastewater goes on to finer filtration processes.

Anita

Anita