- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

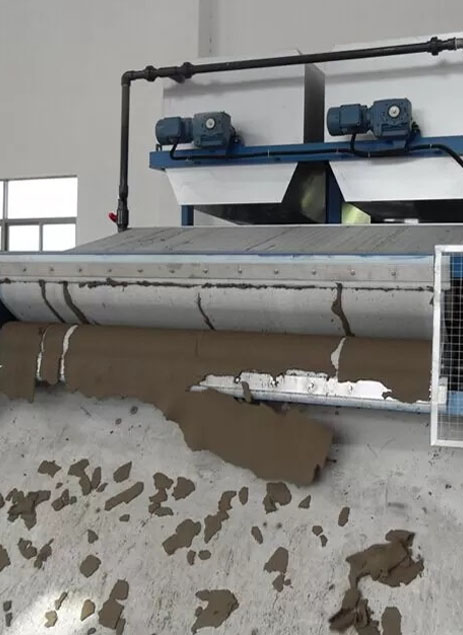

Sludge Dewatering

SLUDGE DE-WATERING

Wastewater sludge dewatering is a crucial process in wastewater treatment plants and various industrial sectors that generate sludge as a byproduct of their operations. Sludge is a semi-solid mixture of water, organic matter, and inorganic particles that remains after the wastewater treatment process. Dewatering involves removing a significant portion of the water content from the sludge, transforming it from a wet, slurry-like substance into a more manageable and less voluminous material. This process holds substantial importance for several reasons:

Volume Reduction: The primary benefit of dewatering is the significant reduction in the volume of sludge. Removing water from sludge leads to a reduction in its weight and volume, which lowers transportation and disposal costs. This is particularly important as sludge disposal can be expensive, and reducing the volume makes it more cost-effective to handle and transport.

Cost Savings: As mentioned, dewatering reduces the weight and volume of sludge, which translates to lower transportation and disposal costs. Since many wastewater treatment plants and industries have to manage large quantities of sludge, even a slight reduction in volume can result in substantial cost savings over time.

Resource Recovery: Depending on the specific characteristics of the dewatered sludge, it might be suitable for further processing to recover valuable resources.

For instance, some dewatered sludges can be used as fertilizers, soil conditioners, or even converted into biogas through anaerobic digestion, thus turning waste into a resource.