- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

Integrated WWTP

Integrated WWTP

pathogenic microorganisms, and chemical elements including heavy metals, which reach distant areas due to the medium of dispersion and thereby create an ecological discomfort and harmful health hazards in life forms, wastewater generated from various sources such as municipal, domestic, and industrial activities is the primary global environmental concern. Although it is currently impossible to prevent wastewater from being released into the environment, it is possible to mitigate its gravely detrimental impacts on people and the entire ecosystem by treating the wastewater using a variety of techniques. Therefore, before the wastewater is disposed of into the environment, sufficient treatment is necessary.

Integrated wastewater treatment

By combining two or more biological, physical, and chemical processes, integrated treatment techniques have been used extensively to treat/eliminate undesired color, target chemicals, and toxicity from wastewater or polluted environments.

Types of wastewater treatment

Three stages are used to remediate wastewater:

Primary Treatment

Sewage is placed in a basin during initial treatment so that solids (sludge) may fall to the bottom and oil and lighter materials can rise to the top. The residual liquid can then be sent for further treatment once these layers have been removed. Sludge digestion is a distinct procedure used to remediate sewage sludge.

Sludge Digestion

During initial treatment, sewage sludge that was scraped from the bottom of the settling tank is better handled from wastewater.

Secondary Treatment

The removal of floating and dissolved biological materials during secondary treatment frequently involves the use of microbes in a controlled setting.

Tertiary Treatment

Water that is being released into a delicate ecology undergoes tertiary treatment, often known as "effluent polishing."

Sewage treatment Plant and its procedures

The process of purifying sewage water and reusing it for gardening, agriculture, and other general purposes is known as a sewage treatment plant (STP).

Here are a few STP procedures:

-

Activated Sludge Process.

-

Moving Bio Bed Reactor (MBBR)

-

Membrane Bio Reactor (MBR)

-

Electro Coagulation System.

-

Sequential Bio Reactor (SBR)

-

Rotating Bio Reactor (RBC)

Stages of Wastewater treatment process (WWTP)

1. Bar Screening

Large objects must be removed from the influent to avoid harming the facility's pumps, valves, and other machinery.

2. Screening

Grit removal by passing influent over or through a grit chamber.

3. Primary Clarifier

initial separation of wastewater and solid organic materials.

4. Aeration

To promote the conversion of NH3 to NO3 and to give air for bacteria to continue to multiply and develop, air is pushed into the aeration tank or basin.

5 Secondary Clarifier

Pumping treated wastewater through a secondary clarifier enables any persisting organic matter to separate out of the flow of treated water.

6 Chlorination (Disinfection)

To eliminate any leftover bacteria in the contact chamber, chlorine is introduced.

7.Water Analysis & Testing

The functioning of the plant depends on testing for the right pH level, ammonia, nitrates, phosphates, dissolved oxygen, and residual chlorine levels to comply with the NPDES permit.

8 Effluent Disposal

Clean water is restored into the environment once it has complied with all permit requirements.

SEWAGE TREATMENT PLANTS

We provide Activated Sludge Process (ASP)-designed and -manufactured Sewage Treatment Facilities. Our plant's purified water may also be utilized for washing and flushing. Additionally, we develop plants utilizing cutting-edge technologies including MBBR, UASB, and Sequential Batch Reactor (SBR). The following technologies are covered:

MBBR technology: It is more efficient than ASP and uses less space, which reduces costs. Where there is a lack of room, this strategy works well. Even washing and gardening may be done with the water that has been treated using this method.

UASB technology: Customers like it because of its low power usage in comparison to competing technologies on the market. Additionally, after being converted to energy, the biogas produced using this method may be utilized to power both the high-capacity plant and the whole facility. Even gardening may benefit from the purified water produced by this facility.

Sequential Batch Reactor (SBR): It aids in batch wastewater treatment, making it ideal for usage in situations where little waste water is produced each day. The method also reduces operating expenses and sludge production. Neither a separate clarifier nor a settling tank is required.

We provide a wide variety of sewage treatment plants that are used on both the domestic and international markets. These items are produced with the most up-to-date methods and cutting-edge equipment, and we provide them in an affordable and dependable way. Our products are freely accessible in a variety of specifications, and we test them using various quality controllers based on numerous quality parameters. To our customers, these items are offered along with specialized services.

Combined Sewage Cum Effluent Treatment Plants

-

We provide a variety of Combined Sewage and Effluent Treatment Plants that serve two needs at once. These are effectively built to handle and treat both effluent and sewage simultaneously. This facility effectively removes water from sewage and effluents, making it suitable for various uses including farming, gardening, and washing. In addition to being available in standard specifications, our selection of mixed sewage and combined effluent treatment facilities may also be tailored to fit the various needs of our clients.

Features: -

Low price

-

Compact in size

-

low electricity demand

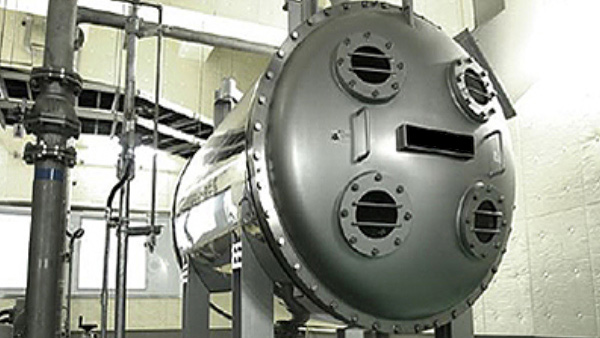

Integrated Sewage Treatment Plant

-

We provide a top-notch selection of Integrated Sewage Treatment Plants, which are utilized to treat both sewage water and solid wet waste together. These items are utilized as a substitute for fossil fuels, and the treated water is put to many uses, including washing and flushing as well as farming and gardening. Our clients may get our items at fair costs, and they are made using the most recent technologies.

Uses: -

Companies and industries

-

Estates & Hotels

-

Education Establishments

Anita

Anita