- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

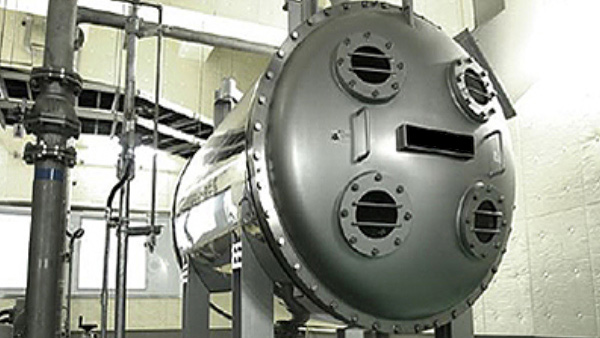

Spray Filter

Spray Filter

Spray filter

The degree of fractionation and/ or micros training depends on many factors; inlet consistency, spray pressure, inlet filler content, micron opening size, and particularly fines content of the fiber fraction. The following results can be expected Coarse impurities are separated out. All the water is microstrain. The fiber fraction is retained by the cloth and can be recovered. Changes in fiber content by the KROFTA Spray Filter are minimized so that subsequent clarifiers operate under a uniform load. The KROFTA Spray Filter improves the operation of clarifiers especially floatation ones, as it aerates the effluent making it more adaptable to floatation.

Simple operation: few moving parts and very low rpm

- Simple operation: few moving parts and very low rpm

- Self-cleaning: built-in cleaning shower saves down-time

- No freshwater required: cleaning shower nozzles are an open, non-clogging type. Filtered water can be used in the shower

- Easy maintenance: wide access door allows easy changing of the cloth and access to the interior

- Inexpensive filter screens

- The window wiper operated manually is located on the inner side of the door.

Purpose :

The KROFTA SPRAY FILTER is specifically designed for the filtration of effluents containing from 20 PPM to 5000 PPM of solids. A fine mesh cloth with openings

from 75-500 microns is used as the filter media, either to separate long fibers from clay and filler or as a safety filter for showers using clarified water. The KROFTA SPRF meets the

need for high throughput units that can handle wide variations of solids content. It is equipped with a cleaning shower which greatly reduces the need to remove the cloth for cleaning.

Anita

Anita