- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

Industrial Water Treatment Plants

Industrial Water Treatment Plants

Dissolved air floatation is a reliable separation process to remove solids from liquids.

The most up-to-date clarifier based on this principle has been successfully used since 1973 for fibre recovery in paper mills and for a variety of solid/liquid separation processes.

Worldwide installation of more than 3,500 supercells and installation of over 300 units in India alone, speak for the reliance placed by reputed industries and municipalities on the efficiency of Krofta equipment.

The concept of dissolved air floatation for removing solids from liquids was perfected by Mr Milos Krofta of U. S. A. In the 70's and today, Krofta technologies corp. , U. S. is one of the oldest and professionally established suppliers of water and wastewater treatment equipment in the world.

Working Principle :

Air is dissolved under pressure in the liquid, which is then released to atmospheric pressure in the floatation cell. As the microscopic air bubbles come out of the solution, they attach to the suspended solids in the liquid, causing them to float to the surface forming a thick sludge. A special skimmer removes the sludge with the help of a patented 'Krofta spiral scoop and pours it into the stationary centre section from where it is discharged by gravity for either recycling or disposal.

The unique compact and efficient design are made possible by the use of the principle of "zero velocity".

The "Krofta" supercell is smaller in surface area for its capacity, because, a very high specific clarification degree is attained (160 to 200 ipm/sq mt. ). The water level in the tank is as low as 40 cms, which reduces the size and the weight of equipment, and, the retention time is just 3 minutes.

Construction :

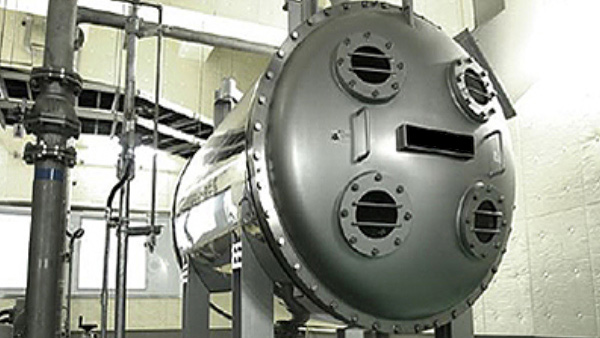

Constructed from epoxy-coated mild steel, the "Krofta" supercell is delivered in parts that can be flanged together.

The "Krofta" supercell does not require a heavy foundation or support structure as the total load factor when filled with water would be less than 730 kg/sq. Met.

Operation :

The central part of the supercell consists of two circular sections. The inner section contains the sludge well and is fixed while the outer section rotates along with the spiral scoop at a speed synchronized with the flow. The inlet, outlet and sludge removal mechanisms are all located in the central rotating section.

The variable speed gear motor drives the rotating elements and the scoop, for which electrical current is fed from a rotary contact mounted on the central shaft.

Unclarified water is released through a rotary joint in the centre of the tank, it then passes into the distribution duct that moves backwards with the same velocity as the incoming water, thus creating zero velocity. The settling and the floatation processes take place in this quiescent state. The patented "Krofta" spiral scoop takes up the floated sludge pouring it into the stationary centre section, from where it is discharged by gravity for either recycling or disposal.

Anita

Anita