- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

Application Of DAF In Slaughterhouses

Application Of DAF In Slaughterhouses

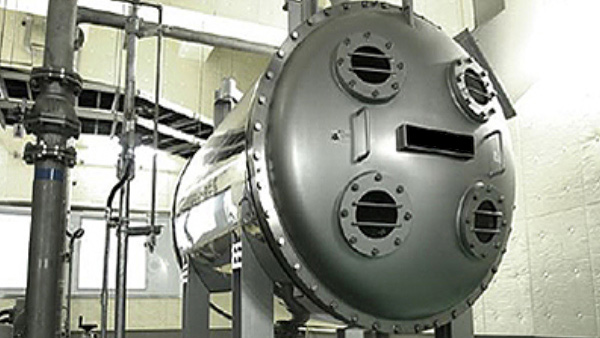

DAF system

has increased with an overall increase in the global food demand. Wastewater from a cattle slaughterhouse is a mixture of the processing water from both the slaughtering line and the cleaning of the guts, which causes a large variation in the concentration of organic matter. The main pollutant in slaughterhouse effluents is organic matter. The contributors of the organic load to these effluents are paunch, faeces, fat and lard, grease, undigested food, blood, suspended material, urine, loose meat, soluble proteins, excrement, manure, grit, and colloidal particles.

Untreated slaughterhouse waste entering into a municipal sewage purification system may create severe problems, due to the very high biological oxygen demand (BOD) and chemical oxygen demand (COD). Therefore treating of slaughterhouse wastewater is very important for the prevention of high organic loading to municipal wastewater treatment plants. The most common methods used for treating slaughterhouse wastewaters are fine screening, sedimentation, coagulation-flocculation, and activated sludge processes.

Among Physico-chemical processes, dissolved air flotation (DAF) and coagulation-flocculation units are widely used for the removal of total suspended solids (TSS), colloids, and fats from slaughterhouse wastewaters. The advanced quality of DAF-effluent can be accomplished by managing the chemical pre-treatment and the operating conditions of DAF system. Separation of solids from water using DAF systems is carried out by bringing air into a PSWW influent, through the bottom of the tank.

Krofta with its vast experience can offer Solutions for the treatment of Effluent generated from Meat & Poultry Industries. The main features are:

- To efficiently reduce COD, fats, and grease.

- To efficiently reduce FOG and TSS.

Anita

Anita